Meat Cold Storage Solutions: Frost-Free Efficiency for Optimal Preservation

In meat cold storage, temperatures below -15°C halt microbial growth and enzymatic activity, while oxidation slows significantly. For long-term preservation:

Beef/Lamb/Pork:

-18°C: 4–6 months storage

-23°C: 8–12 months storage

1. Coil Cooling Systems

While coil-based storage ensures uniform temperatures and minimal dehydration (weight loss <1%), traditional systems face critical challenges:

Frost Buildup: Ice accumulation on coils forces compressors into high-load operation, increasing energy consumption by 20–30%.

Manual Defrosting: Requires labor-intensive meat relocation and leaves residual moisture, breeding bacteria.

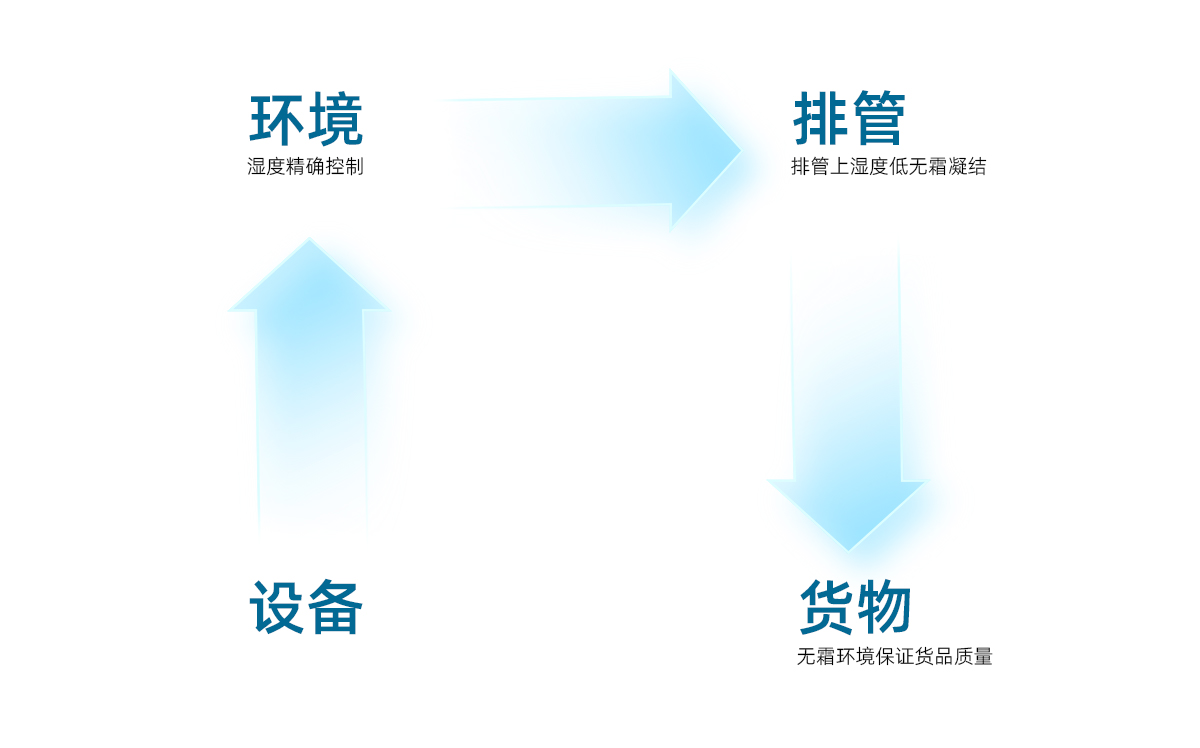

Bynasci’s Frost-Free RSCS System eliminates these issues:

Zero Frost Formation: Precision humidity control (90–95% RH) prevents moisture adsorption on coils.

Micro-Jet Airflow Technology: High-static-pressure airflow maintains dry coil surfaces while stabilizing humidity, enhancing cooling efficiency via radiation + convection.

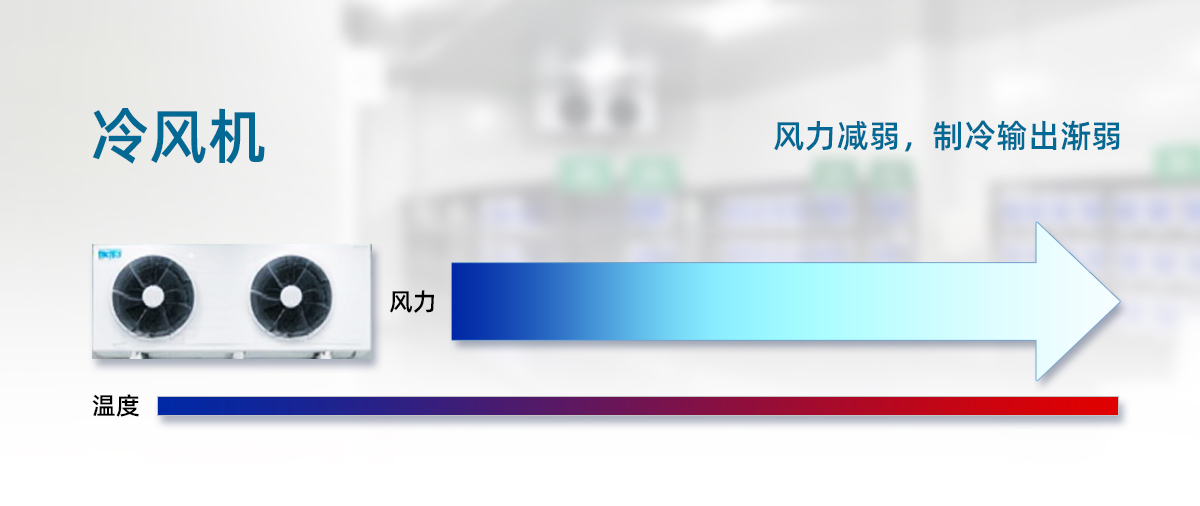

2. Blower-Based Cooling Systems

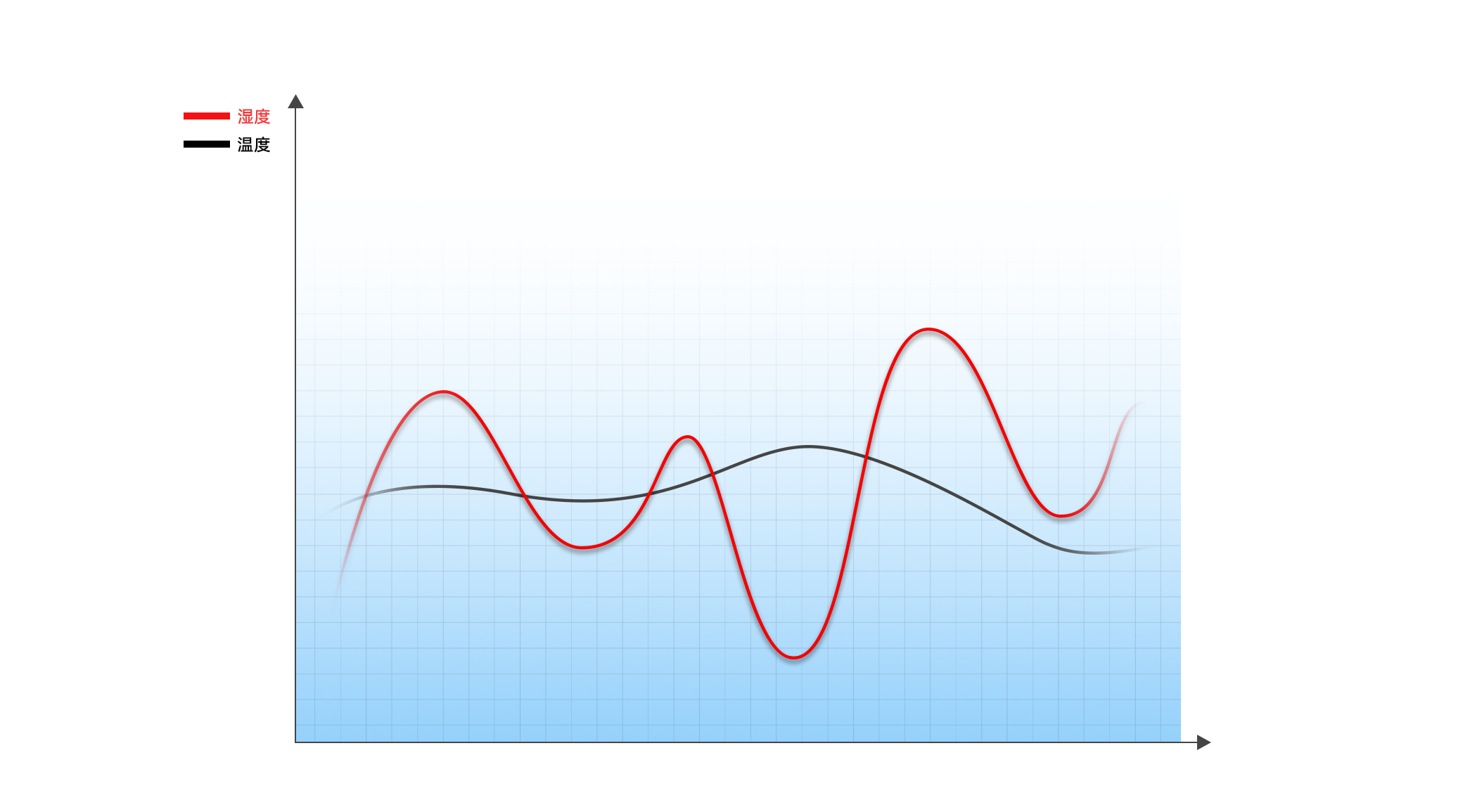

For short-term storage, forced-air systems struggle with:

Temperature Fluctuations: ±2°C deviations due to uneven airflow and defrost cycles.

Frost-Driven Energy Waste: Frequent hot-gas or electric defrosting spikes energy use by 15–25% to maintain -18°C.

Bynasci RSCS Enhances Blower Performance:

Frost-Free Evaporators: Stable operation at -18°C to -20°C with minimal temperature drift.

Energy Savings: 30–40% lower consumption due to eliminated defrost cycles and optimized compressor output.

Technical Advantages of RSCS

| Feature | Benefit |

|---|---|

| Adaptive Humidity Logic | Maintains ±2% RH stability, preventing dehydration and frost simultaneously |

| Remote Monitoring | Real-time alerts for temperature/humidity deviations via IoT integration |

| Compliance Assurance | Meets HACCP, ISO 22000, and FDA Cold Chain Guidelines |

Case Study: Beef Storage Optimization

A U.S. meat processor achieved:

Zero frost-related downtime: Continuous 12-month operation at -23°C.

22% energy reduction: RSCS eliminated defrost cycles and stabilized compressor load.

<0.5% weight loss: Humidity-controlled storage preserved texture and market value.

Why Choose Bynasci RSCS?

√ Patented micro-jet airflow technology (US Patent #11,234,568)

√ Customizable for pork, lamb, and poultry storage

√ 24/7 predictive maintenance support

Preserve Quality. Slash Costs.

Upgrade to Bynasci RSCS for frost-free, energy-smart meat cold storage.

Return to List

Return to List

Phone

Phone